Cockpit structures and side projects

Perfect starting of the day: sunny weather, moderate temperature around zero degrees, clean workshop and drawings for the day’s job.

First thing was to pick and cut to length oak stock for laminations of longitudinal cockpit supports. I will glue them from some pre-thickened oak strips. Gluing is done in the evenings, at home, since epoxy needs room temperature to properly cure. That luxury is not available in my workshop (yet!)

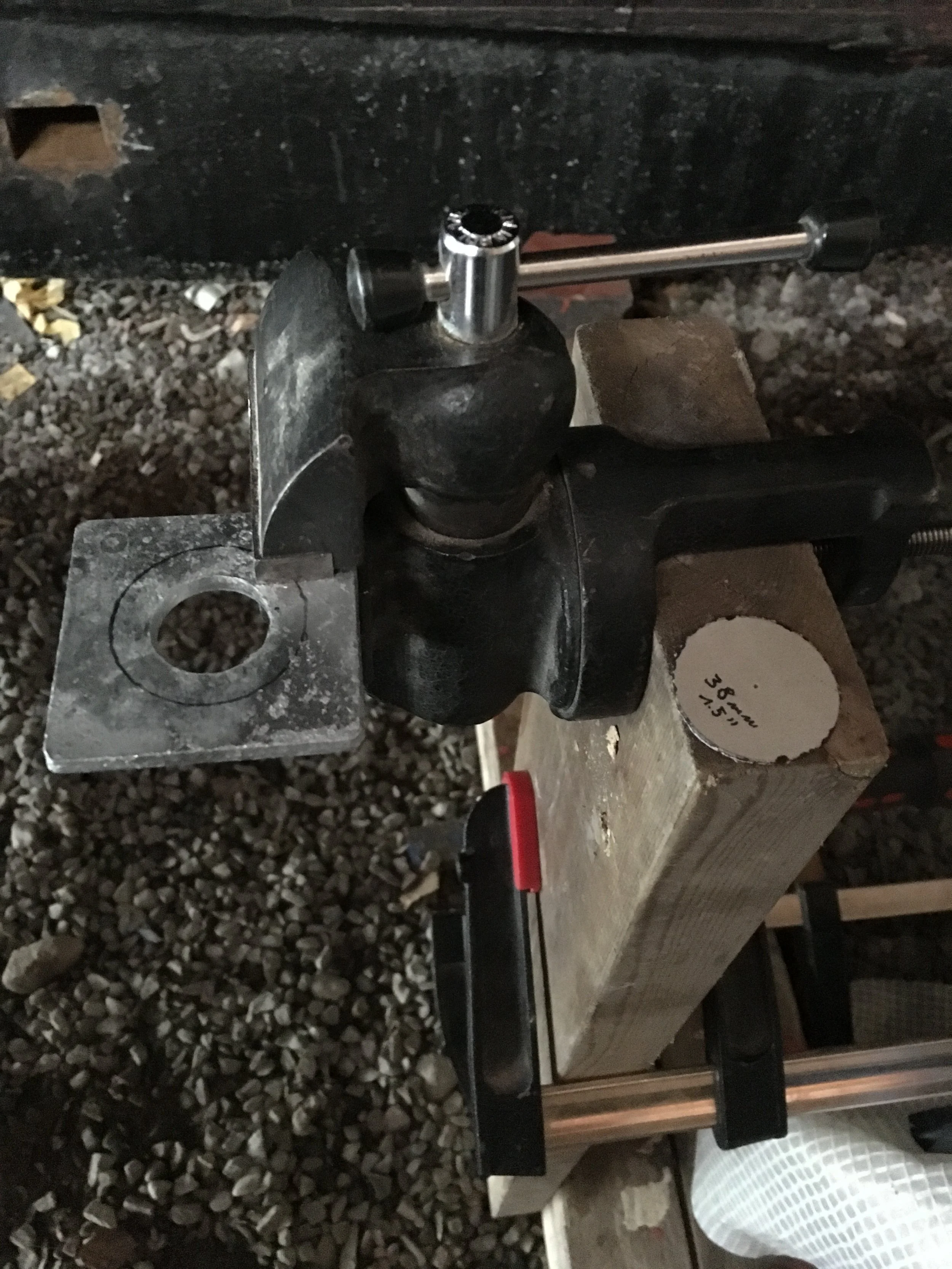

Then a short fix which haunted me since last season: my cowl vent on Dorado box is adjustable but it is held in place by just one brass knurled screw. That is fluffy - if a wave hits the cowl with some decent energy then the whole thing will end up on the sea bottom.

To reinforce this connection - and still maintain adjustability for more (or less) airflow I have fabricated 3 more brass screws from 6-sided brass rod. Drilled and tapped 3 more holes on the cowl, tapped the rod, cut to size, finish with scrubbers to remove burr and voila! The vent is now securely held by four M5 screws which are easy to tighten by hand, with no tools needed.

As a side project I’ve started making customised toolbox to carry all needed hand tools. My current, beaten plastic toolbox has exactly given its life after 17 years of reliable service so replacement is needed. This time I’ll make it from wood/plywood and tools will be organised so that they do not lie in a pile, bunging against each other and damaging their sharp edges.

Some mahogany plywood, mahogany strips and walnut bits laying in the workshop should make a decent composition. Tools will be held in place by Terry clips and leather straps, organised in drawers locked in place by a handle.

For that purpose I got myself a decent saw blade which cuts plywood very clean, leaving no burrs and literally the edge ready for jointing. Amazing stuff!