Spring winds

It is warm recently so snow is melting and wind smells spring.

It is about time to put “spring dress” on Meritaten, to protect her for drying out, especially during such dry, warm windy days.

Björn called, in his usual way, if he can come in 20 minutes to deliver keel bolts. Oh yeah! Sure!

This guy is really something - old-timer in good sense of this word. Quality of his job is always outstanding, even in case of these bolts. Even though I told him that my boat is not a Hasselblad he kept asking about tolerances in dimensions. He took it even further and checked with Swedish Institute which deals with marine structures if the steel we chose is proper for this application. And how should we protect it from corrosion.

I admire this type of mechanics!

Björn made me 2 sets of bolts so that I will have them at hand if in 10-20 years I decide to replace the bolts.

I tried them on the boat and, of course, they fit perfectly. He took away 400 micrometers from the diameter so that I can cover them in epoxy, to inhibit rust.

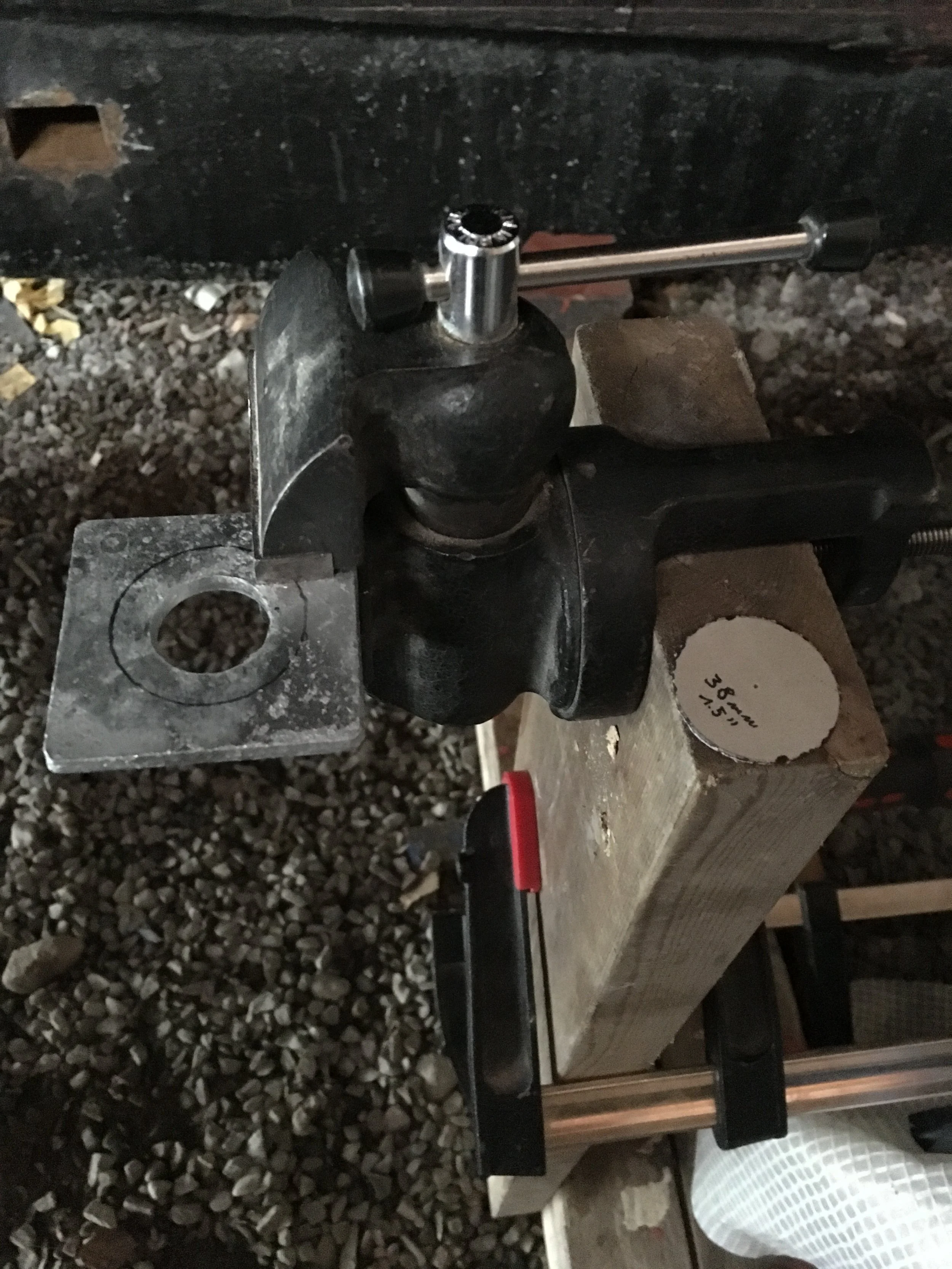

Since I started early in the boatyard - no one was around - I decided to take this opportunity and make some noise with angle grinder. I needed to adjust washers to fit old floors.

After lots of noise and rain of sparks new washers were ready.

I then moved on onto further demolition of cockpit floor.

This job goes like blood from the nose: removing old plywood and oak which was screwed to the hull with brass screws and adhesive filling compound (probably Sika - everybody seem to love this stuff!).

After all these years there is no way I can unscrew brass screws - they crack and disintegrate upon attempt. That is why one should stay away from brass fastenings on a boat!

In the end I need to split the wood with chisels, cut the screws and drill sets of holes to remove everything in parts. Messy job.

Back in my workshop I fitted big washer to new floor timber #3.

Activity which produces lots of dust and noise but the effect is OK.

So now the floor timber is ready for painting and installation. I will seal end grain with epoxy and paint the rest with bilge paint (red iron oxide in linseed oil). Top face will be finished bright, with varnish, as it will be seen on floor level.

Once this is done I can drop it into its place, install new keel bolt, rivet it to frames and screw to garboard and 2nd plank.

My new keel bolts are metric so I can now use a variety of nuts. For this purpose I chose M18 standard, galvanised nuts. It is interesting to note how the dimensioning standards changed (around 90’ I think).

Comparing side by side old 5/8” UNC nut with M18 nut shows that the old standard had more beefy dimensions: both nuts have almost the same dimension while opening differs significantly.

The replacement bolts are made much stronger than originals. I chose also thicker and bigger washers which should work better in distributing load.

Anyway, I’m gonna feel much better having three such new bolts in the structure. In principle one can lift my whole boat on one of these screws, still having a margin of 200-300% strength.

Running aground or getting beaten in bad weather requires having backbone structure as strong as it can be.

Besides, it was really the last moment to change these bolts!