The problem I have with any glue joint is that it has a limited lifespan after which the joint fails.

We know already now that cold moulded boats are still in good condition after 40 years. But still no one knows how long epoxy joint will hold. My boat was glued with Cascoflex during assembly. It is a very good glue, water resistant and withstanding boiling test but still the shipyard used traditional mechanical fastenings (copper rivets) to keep planks on frames movable and mechanically connected should the glue fail.

Well, after 60 years there is not much of this glue left in my boat. She is now fully traditional plank-on-frame construction but still watertight due to being mechanically assembled, not glued.

So I have reservation for glue joints - as George Buehler used to say: I trust a glue joint only if there is a metal bolt running through it.

But… if the epoxy will last 40 years in good condition - why should I care about what will happen then???

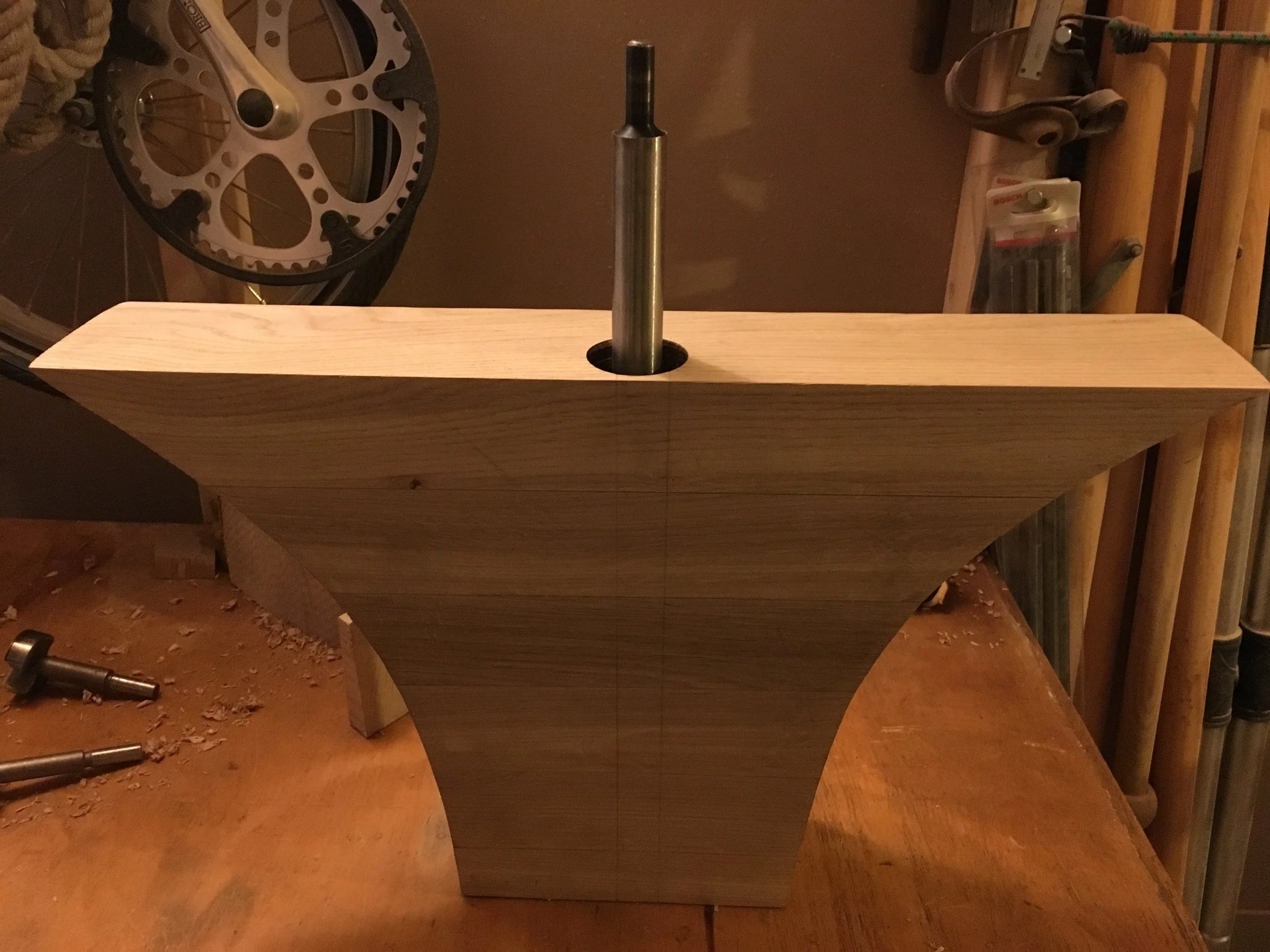

So the plan now is to install this floor timber with new keel bolt - once Björn is done with making them - and filling the void around it with thin West system epoxy. That should penetrate the wood and fill any gaps around the keel bolt, securing it in tight fit and isolating from acidic oak. To prevent the bolt from being permanently glued to the floor I will cover it with grease or wrap a thin foil around it. Once the epoxy cures I should be able to bang the bolt down into the keel timber.

What will I do differently with next floor timber?

Several things:

square and join the wood more carefully so that 4 faces are true and perpendicular. That should make it easier to align any jig or drilling aid

if I will use laminated construction, like in the current floor #3, I might fit all parts into bilge without prior gluing them. This will give me opportunity to drill shallow holes one-by-one. More work but seems safer

I will use wooden dowels to connect all parts after fitting and before gluing. That will prevent them from gliding during gluing and allow me to disassembly the stack for drilling on the drill press. Saves much time in post-treatment as the component will just need to be cleaned from hardened epoxy and not made square again

if I happen to be drilling through so thick timber again I will get myself proper drills for the job. Probably auger drills would be most suitable: https://www.fine-tools.com/fisch-schlangenbohrer.html

So now I move to another jobs on Meritaten. When keel bolts finally arrive and temperature allows for using epoxy resins I will install this floor to finish the job.

And if - although I doubt it - I manage with other scheduled repairs before spring I might re-make this floor timber. This time with better drilling accuracy.

If not - there is still next winter ahead.